Concrete Slab

A concrete slab offers a continuous, solid base for the dome structure. Here are some tips and tricks to help you pour your concrete slab.

A concrete slab offers a continuous, solid base for the dome structure. Here are some tips and tricks to help you pour your concrete slab.

a quick step-by-step guide

once the slab has been poured, you are going to have great difficulty connecting services if they have either not been laid in the right spot or not laid at all.

this is relatively straight-forward to understand. Depending on the gradient of the ground, retaining walls may need to be added to minimise risk of mudslides or debris falling into your site.

this will minimise issues with undergrowth, insect and animals. Methods such as spraying the area and laying weed mats or geofabric are simple yet effective ways to minimise these potential issues from arising.

this is crucial for the long-term success of your concrete slab. Since the area has been levelled for the pad, you do not want water to run underneath the slab and sit there as this can create erosion. Make sure the drainage runs downhill (remember kids, water runs with gravity, not against it).

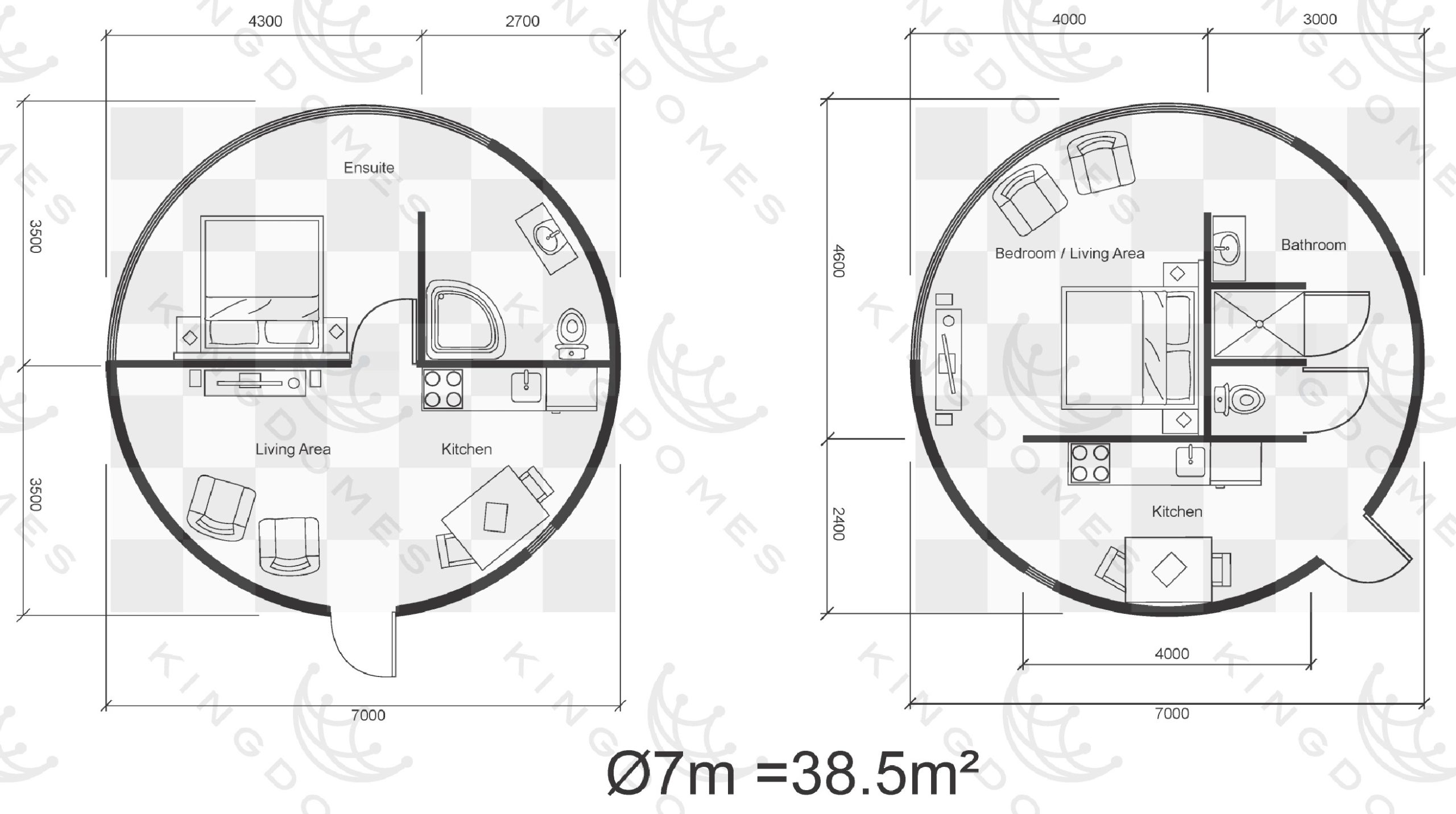

using your finalised floorplan, you should be able to work out where your internal walls are located. This is a great reference to stick your service connections (think electricity, water inlets/outlets, A/C and gas) through. It will also reference where your bathroom exit ports are. You do not need to connect these services just yet, just make sure the relevant piping and conduits are where they need to be.

this will hold your slab together while it cures and settles. Just make sure you lock it in place using star pickets or posts of some sort to ensure that the formwork doesn’t shift during the pour stage.

this is where the structural integrity of the slab comes from so do not skip this step.

you are now ready to pour the slab. We have had clients who have gone through the trouble to have a slight fall from the centre to the outer perimeter of the dome to minimise any stagnant water sitting on the slab and potentially running into the dome.

this is an important step to ensure minimal hiccups in the future. There are tools and equipment that can make this process easier/faster. We have had clients who have made a slight fall from the centre of the slab, outward. Though not necessary, it can definitely help with pooling water.

once the slab has been set, allow a couple of days for it to cure before building your King Dome. Failure to do this can lead to the King Dome not being anchored properly to combat high winds and shifting.

Here is an example of a concrete slab that will cater for our 7m King Dome. Please note that the entry point (door) has not been factored into this basic drawing. We will send you orthographic plans with exact measurements for your King Dome. All our domes require roughly a 100mm lip to allow for the anchor plates and press bars. This will bring the slab to 7200mm minimum (not including the doorway).

As you can see in the photo, we typically recommend a slab thickness of between 100-120mm (please consult with a tradie to confirm this as there will be multiple factors that will determine the optimal thickness).

We recommend creating a 250-400mm wide (with centre being roughly at the 7m mark, or which ever size of dome you are catering for) and 250-350mm deep channel on the outer perimeter of the slab (depending on dome size and wind conditions). This is so that our anchor points have sufficient concrete to grab onto without jeopardizing the integrity of the slab itself.

click below for more information

Building your Foundation or Building your King Dome.